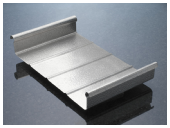

Bradclad - PROSEAM

Bradclad - PROSEAM

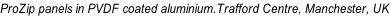

is manufactured from aluminium coil in alloys from the 3000 and 5000 series. These typically contain over 90% aluminium, but also significant percentages of manganese and magnesium. The resultant metal is formable, strong and corrosion resistant.

is manufactured from aluminium coil in alloys from the 3000 and 5000 series. These typically contain over 90% aluminium, but also significant percentages of manganese and magnesium. The resultant metal is formable, strong and corrosion resistant.

Aluminium can be fully recycled and at a much lower cost than primary production from bauxite. However, world demand for the metal means that mill supply can only include some recycled material. In years to come, an aluminium  roof will provide additional benefit to the building owner from its high residual scrap value.

roof will provide additional benefit to the building owner from its high residual scrap value.

Paint finishes

Painting aluminium may increase the life expectancy of the

panel, but will also ensure continuity of colour across the roof.

panel, but will also ensure continuity of colour across the roof.

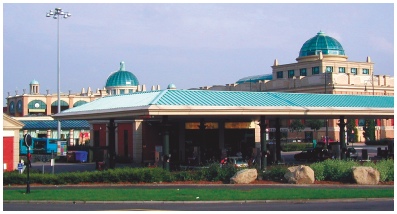

Bradclad use recognized international suppliers of pre- panel. For quantities of 500 square metres or more,

panel. For quantities of 500 square metres or more,  can be offered in any colour in PVDF or ARS coatings. Smaller quantities may be available from stock or by special arrangement.

can be offered in any colour in PVDF or ARS coatings. Smaller quantities may be available from stock or by special arrangement.

Alternatively  panels can be offered in polyester powder finish. This more costly method is used to colour coat panels once they have been formed. There is a limitation on panel length, but not on quantity and even single panels can be powder coated to a required colour.

panels can be offered in polyester powder finish. This more costly method is used to colour coat panels once they have been formed. There is a limitation on panel length, but not on quantity and even single panels can be powder coated to a required colour.

Welding

The fact that aluminium can be readily welded, even in thin gauges, allows  panels to be detailed in a variety of ways, offering a tremendous range of design opportunities

panels to be detailed in a variety of ways, offering a tremendous range of design opportunities

in Copper

in Copper

Copper is a natural material that has been used for centuries to clad building exteriors. With a virtually indefinite design life, it is extremely durable and resistant to corrosion even in aggressive environmental conditions.  panels in copper are manufactured to the same dimensions as

panels in copper are manufactured to the same dimensions as  in aluminium – in widths of 300 and 400mm. The copper used is C106 alloy, accurately tempered to produce high strength coil strip ideal for rollforming.

in aluminium – in widths of 300 and 400mm. The copper used is C106 alloy, accurately tempered to produce high strength coil strip ideal for rollforming.

Copper requires no decoration, maintenance or cleaning and is dimensionally stable over time. Newly produced copper has a bright reflective appearance. Exposed to the elements, this bright finish quickly weathers to an attractive chestnut brown, which eventually develops into the familiar green patina that characterises the metal. This patina will reform if damaged, ensuring great durability.

To maximise specifier choice, Bradclad can supply  copper panels in different finishes, including pre-

copper panels in different finishes, including pre-

in Zinc

in Zinc

Zinc is a naturally self-

Zinc is a naturally self-

zinc panels can be supplied in grey “quartz zinc”, or slate grey “anthra zinc”.

zinc panels can be supplied in grey “quartz zinc”, or slate grey “anthra zinc”.

Zinc is a soft metal that lacks the span capability of harder metals.  zinc panels therefore require some form of support during installation, usually in the form of semi-

zinc panels therefore require some form of support during installation, usually in the form of semi-

Zinc is especially vulnerable to attack from condensation that may form on the underside of the  panel. The panel should either be laid on a ventilating layer, such as a polypropylene pimpled blanket, or treated with a polyurethane coating to prevent attack from occurring.

panel. The panel should either be laid on a ventilating layer, such as a polypropylene pimpled blanket, or treated with a polyurethane coating to prevent attack from occurring.

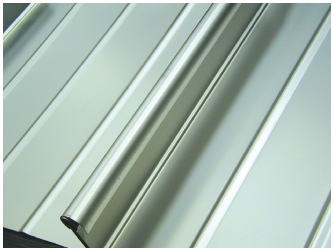

in Stainless Steel

in Stainless Steel

Stainless steel offers a combination of aesthetic and practical benefits. It is visually striking – reflecting light and surrounding colour – non-

in stainless steel is manufactured from 304 and 316 grade steel, the latter being ideal for aggressive industrial or marine applications. Whatever the grade, the material is available in a variety of finishes. Please contact Bradclad for details.

in stainless steel is manufactured from 304 and 316 grade steel, the latter being ideal for aggressive industrial or marine applications. Whatever the grade, the material is available in a variety of finishes. Please contact Bradclad for details.

ProZip panels in copper, Port Regis, Dorset UK

ProZip curved panels in zinc

Clapham, London, UK

Materials

The versatility of  is further enhanced by a range of materials and finishes

is further enhanced by a range of materials and finishes

in Aluminium

in Aluminium

in mill finish aluminium is offered in either plain or stucco embossed form. Aluminium develops an oxide patina to protect the metal from longer term attack.

in mill finish aluminium is offered in either plain or stucco embossed form. Aluminium develops an oxide patina to protect the metal from longer term attack.

It requires no decoration and little long term maintenance.

Aluminium is the most abundant metal in the earth’s crust. It has been used for decades as a building material and it’s lightness and strength make it a perfect choice for roofing.

ProZip in stainless steel 304 BA Leisure Centre, Maidenhead, UK